Warehouse Management

Organize Smarter. Dispatch Faster. Win Bigger.

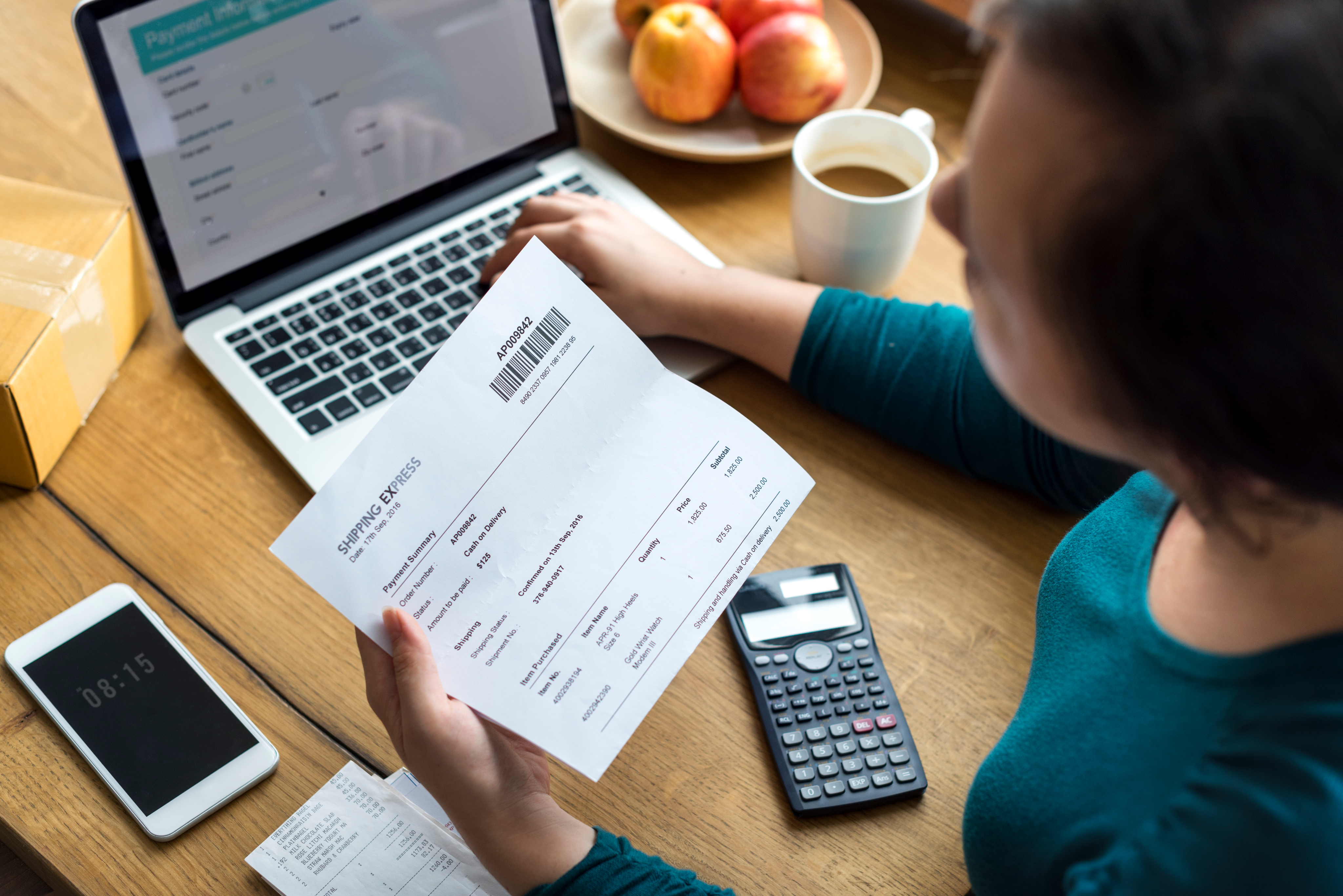

A well-managed warehouse translates to fewer stock errors, faster order picking, and higher space utilization. It directly improves fulfilment speed and customer experience. Structure and streamline warehouse operations with live ERP visibility — improving space, speed, and inventory accuracy.

Run warehouses smarter with real-time ERP contro

Boost storage efficiency and order fulfilment speed

Cut losses with accurate stock tracking